Laser Holding Fixtures

Laser technology has advanced exponentially over the last 10 years. The speed of cutting, the depth of cut and the accuracy of cut have all massively improved. All these improvements are meaningless if the component is not held correctly during the laser cutting process.

Laser technology has advanced exponentially over the last 10 years. The speed of cutting, the depth of cut and the accuracy of cut have all massively improved. All these improvements are meaningless if the component is not held correctly during the laser cutting process.

There are several ways in which this can be achieved without the use of clamps. The first most important factor is to ensure that the exact inside surface geometry is replicated through modelling and CNC machining. We can then provide vacuum generated clamping forces, either by the use of stategically positioned suction cups or a 5 axis machined seal groove and sponge chord seal. Alternatively we can offer a clamping force created by super high strength neodinium magnets. One thing is for sure a wise investment is to ensure that the fixture is not an area where savings should be made by using cheap egg-box type fixturing. You can't sell a box of scrap for more than scrap value !!!!

Examples

-

M/Steel - Vacuum laser Holding Fixture

M/Steel - Vacuum laser Holding Fixture

M/Steel - Vacuum laser Holding Fixture -

Vacuum Laser Holding Fixture

5 Axis Seal Grooves - For Vacuum Laser Holding Fixtures

5 Axis Seal Grooves - For Vacuum Laser Holding Fixtures -

Various Laser Holding Fixtures

Various laser Holding Fixtures - Using Vacuum and Manual Clamping

Various laser Holding Fixtures - Using Vacuum and Manual Clamping -

Al. Alloy - laser Holding Fixture - Using Suction Cups

Al. Alloy - laser Holding Fixture - Using Suction Cups as the primary clamping force.

Al. Alloy - laser Holding Fixture - Using Suction Cups as the primary clamping force. -

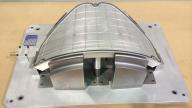

M/Steel - Vacuum Laser Holding Fixture

M/Steel - Vacuum Laser Holding Fixture - 5 Axis Seal Grooves

M/Steel - Vacuum Laser Holding Fixture - 5 Axis Seal Grooves -

Al. Alloy Fixture - Using magnets for the clamping force

Al. Alloy Fixture - Fitted with steel inserts for reacting with Neodinium Magnets.

Al. Alloy Fixture - Fitted with steel inserts for reacting with Neodinium Magnets. -

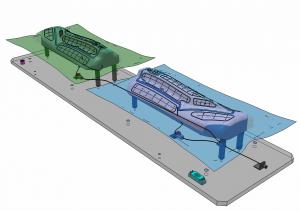

Vacuum Laser Holding fixture - PORT / STBD Cpnts.

Vacuum Laser Holding Fixture - Facilitating PORT and STBD Components on the same fixture

Vacuum Laser Holding Fixture - Facilitating PORT and STBD Components on the same fixture -

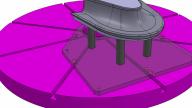

Al. Alloy - Vacuum Laser Holding Fixture

Al. Alloy vacuum laser holding fixture using 5 axis machined seal grooves

Al. Alloy vacuum laser holding fixture using 5 axis machined seal grooves