Reverse Engineering

As computer-aided design (CAD) has become more popular, reverse engineering has become a viable method to create a 3D virtual model of an existing physical part for use in 3D CAD, CAM, CAE or other software. The reverse-engineering process involves measuring an object and then reconstructing it as a 3D model. The physical object can be measured using 3D scanning technologies like CMM's, laser scanners, structured light digitizers, or Industrial C.T. Scanning (computed tomography). The measured data alone, usually represented as a point cloud, lacks topological information and is therefore often processed and modeled into a more usable format such as a triangular-faced mesh, a set of NURBS surfaces, or a CAD model.

As computer-aided design (CAD) has become more popular, reverse engineering has become a viable method to create a 3D virtual model of an existing physical part for use in 3D CAD, CAM, CAE or other software. The reverse-engineering process involves measuring an object and then reconstructing it as a 3D model. The physical object can be measured using 3D scanning technologies like CMM's, laser scanners, structured light digitizers, or Industrial C.T. Scanning (computed tomography). The measured data alone, usually represented as a point cloud, lacks topological information and is therefore often processed and modeled into a more usable format such as a triangular-faced mesh, a set of NURBS surfaces, or a CAD model.

Examples

-

Reverse Engineering Impeller

Scan Legacy equipment to create fully surfaced cad model to enable the manufacture of new pattern equipment

Scan Legacy equipment to create fully surfaced cad model to enable the manufacture of new pattern equipment -

Reverse Engineering Blocker Door

the blocker door required scanning and CAD data creating to enable the component data to be emailed and manufactured at the customers Asian manufacturing plant

the blocker door required scanning and CAD data creating to enable the component data to be emailed and manufactured at the customers Asian manufacturing plant -

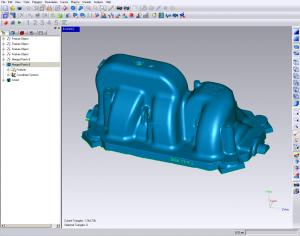

Reverse Engineering Pump Casing

The customer supplies an existing pump casing manufactured before the advent of CAD they require it to be scanned and from the captured cad data create a fully surfaced digital model

The customer supplies an existing pump casing manufactured before the advent of CAD they require it to be scanned and from the captured cad data create a fully surfaced digital model