Assembly Fixtures

Assembly fixtures are required for many applications - Usually to restrain detail parts or sub-assys. to ensure I.C.Y. repeatability and consistency of build. Jigs are either designed by our engineers in-house or made to released drawings and CAD.

Fixtures can either be bench-top, or site levelled and inspected / calibrated using Faro Arms or Laser Trackers depending on the size and the accuracies required.

Examples

-

Assembly Fixture

Assembly Fixture

Assembly Fixture -

Aileron

Business Jet - Aileron final assy. / drilling fixture

Business Jet - Aileron final assy. / drilling fixture -

Turnover - Assy. Fixture

Turnover - Assy. Fixture

Turnover - Assy. Fixture -

Sub Assy. Build Fixture

Sub-Assembly - Build Fixture

Sub-Assembly - Build Fixture -

Sub. Assy Build / I.C.Y. Fixture

Aircraft Sub. Assy. Build Fixtures PORT / STBD - Fixturing.

Aircraft Sub. Assy. Build Fixtures PORT / STBD - Fixturing. -

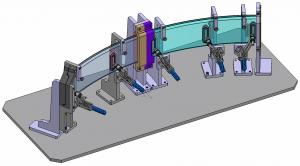

Sub Assy - Drill / Build Fixture

Complex - Build Sub. Assy. and Drill Fixture - Features incorporated due to jig-lock (sliding / swing-over locations).

Complex - Build Sub. Assy. and Drill Fixture - Features incorporated due to jig-lock (sliding / swing-over locations). -

Leading Edge Sub. Assy./ I.C.Y. Fixture

Leading Edge Rib Assy. Fixtures

Leading Edge Rib Assy. Fixtures -

Composite Wing Bond / Assy. Jig

U.A.V. Unmannned Aviation Vehicle - Wing Bonding / Assy Tooling.

U.A.V. Unmannned Aviation Vehicle - Wing Bonding / Assy Tooling.